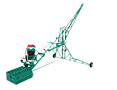

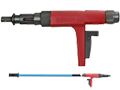

Spray Applied Process: Save time material and labor costs and complete projects up to 4 times faster versus other methods using the Garlock Spray-Applied waterproofing system.

Low Temperature Application: Work more safely by spraying material at temperatures below 260 degrees or less which is classified as Cold-applied in most regions. Eliminates compliance with regulations normally associated with Hot-Applied membranes.

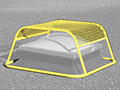

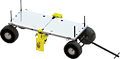

Rugged Design: Experience long term performance, lower cost of ownership and operation with the GSX heavy duty design and construction, engineered for the rugged job ahead.

Diesel Heat and Digital Control: For maximum safety and fuel efficiency, all GSX applicators utilize a fully enclosed chamber diesel heat system. The unique Double boiler design is oil jacketed for indirect heating. Keep product at the precise temperature for application with the on-board digital system with automatic control of application and melter temperatures.

High-Performance Mixing: Eliminate temperature stratification with the specially designed Auger/Agitator. Unobstructed Internal Machine Recirculation ensures unsurpassed heat up and recovery times. Reduce downtime with the heavy-duty pumping system.

Material Capacity |

N/A 150 Gallons |

Heating Method |

N/A Diesel Indirect Heat Oil Jacket Design |

Dimensions |

N/A 170" x 84" x 92" |

Hose Type and Length |

N/A Non Heated, (2) 20' 1" ID, with Yellow Abrasion Cover |

Manufacturer |

N/A Garlock |

Part No. |

N/A GAR-301342 |